Automated Feed Mill Integration for Optimal Production

Services Provided

- General Contracting

- Concept Design

- Structural Engineering

- Site/Excavation/Concrete

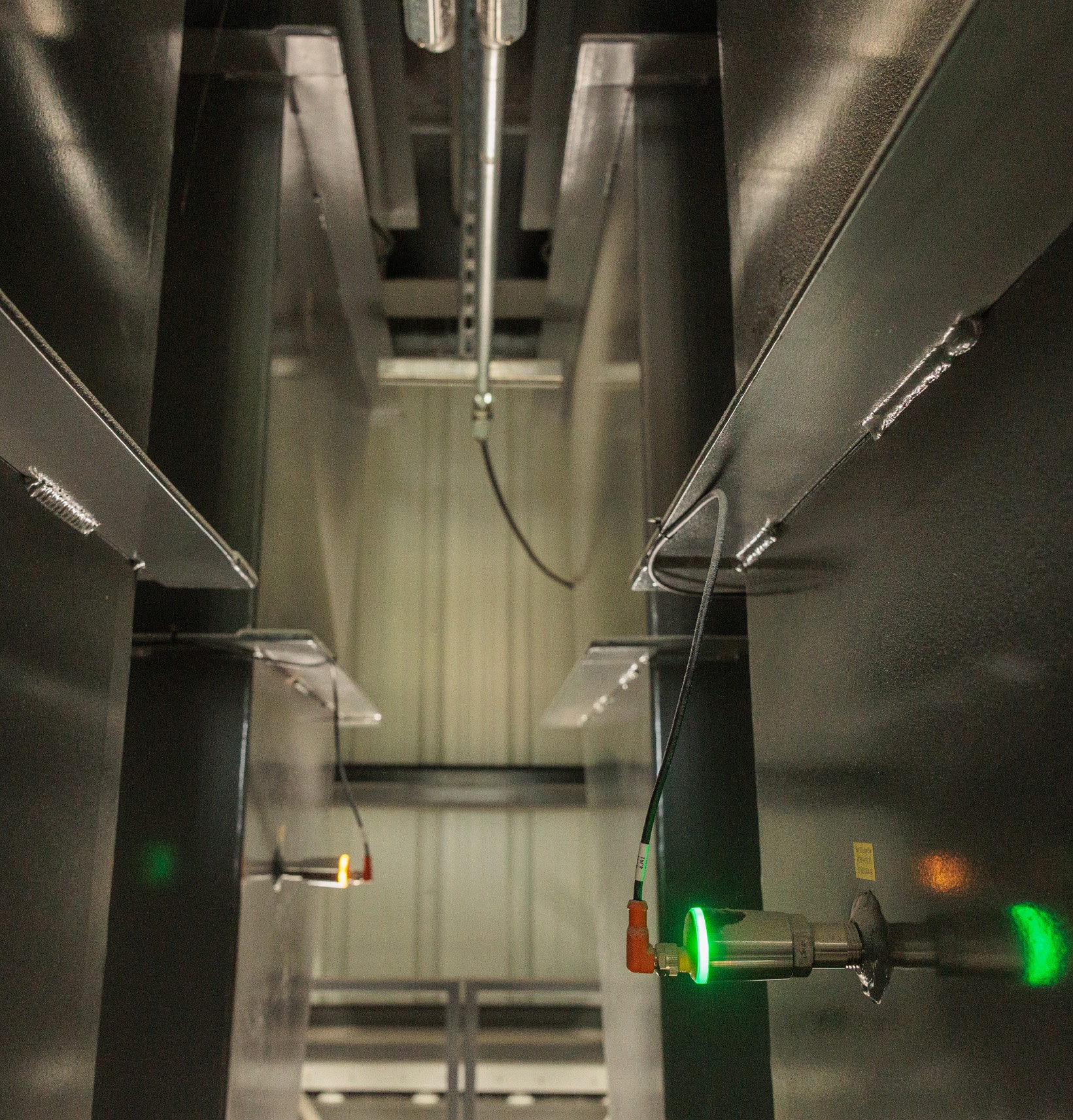

- Electrical / Automation

- Millwright Equipment / Steel Installation

We created Seamless Integration of Fully Automated Feed Mill within Existing Infrastructure to Meet Client's Production Goals

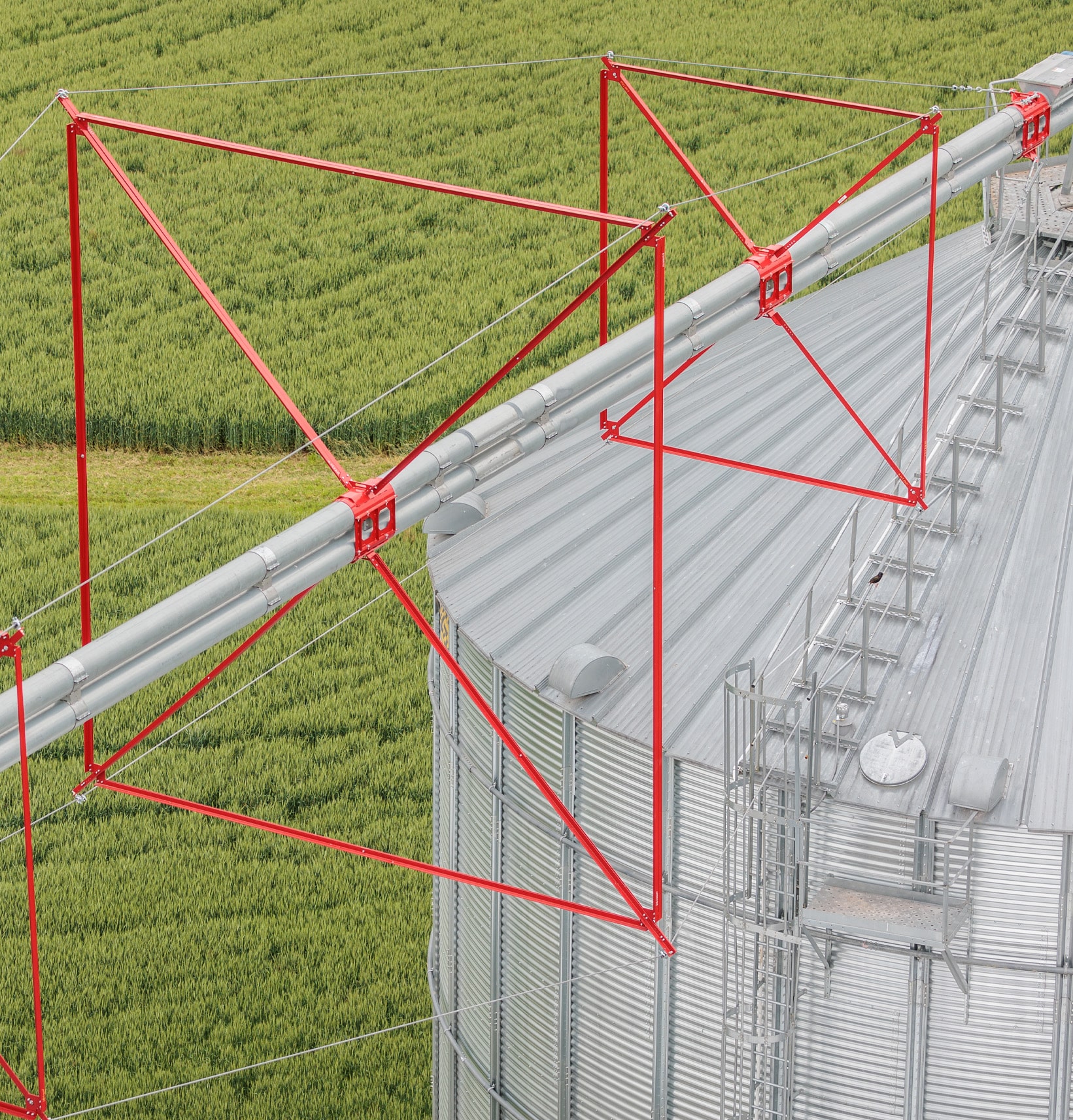

Groff Julius was tasked with constructing a fully automated feed mill capable of producing 2,000 tons of poultry and hog feed per week in a single shift.

The project included the demolition of outdated structures as well as the design and construction of a new loadout facility, milling facility, ingredient storage, and receiving building— all within the constraints of the existing site.

The client required the new mill to be built quickly within their current site and capable of meeting rigorous production targets. We addressed these needs by creatively navigating design challenges and subgrade conditions, developing unique footing designs to accommodate the existing infrastructure.

Completion of this project was wrapped up in 12 months, with the fully automated mill running smoothly and efficiently.